Semi-pre-stressed Pre-stressed Concrete Technology

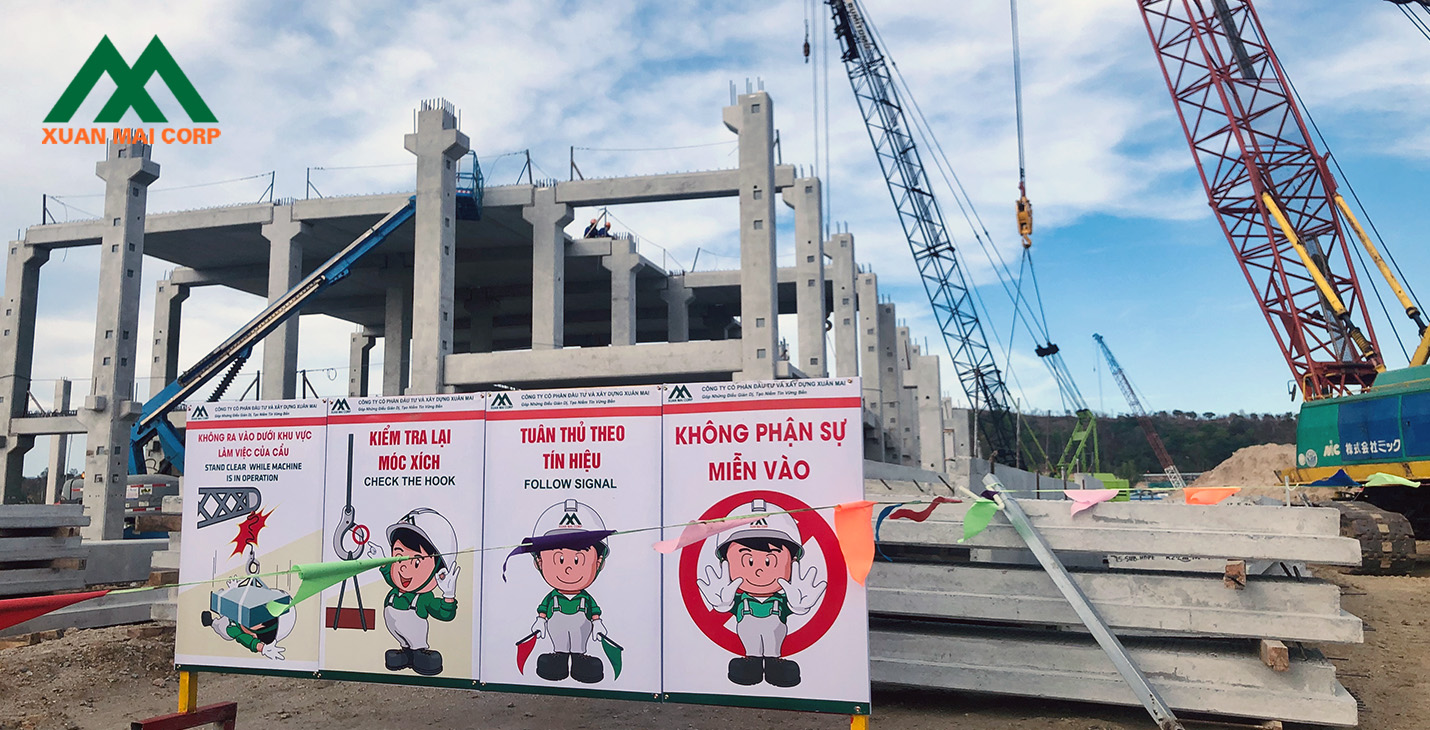

Semi-prefabricated pre-stressed concrete technology has been widely used in the world since many years ago, especially in European countries, America, Japan, Singapore, etc. Technology is a combination of technology. prestressed concrete and pre-engineered concrete technology. Prestressed concrete members will be prefabricated in the factory, then transported to the construction site for assembly. Finally, these prefabricated members will be linked together by joints and/or the concrete backfill at the site.

XUAN MAI CORP has applied Europe's precast concrete technology (Precast Concrete) for hundreds of projects (including high-rise buildings, industrial buildings, public works, and other types of construction projects). other works) in Vietnam over the past 20 years. With a team of well-trained technicians, Xuan Mai has been successfully participating in the design and construction of many projects in Vietnam as an EPC general contractor and real estate developer. The use of post-tensioned floor beam technology applied to the large-aperture floor structure will make it easier to divide and arrange apartment functions flexibly, in accordance with the needs of users; material savings; easily control quality, speed up construction progress at the site, reduce direct labor at the site; safe and environmentally friendly (due to the reduction of emissions and dust at the construction site); reduce dependence and weather. In addition, the floor plate of XUAN MAI CORP uses a foam layer in the middle to help insulate sound and heat well, minimizing the disturbance of the upper floor apartment to the downstairs apartment.

Acotec–Xuan Mai Wall Panel Technology

Acotec-Xuan Mai wall panels are hollow concrete wall panels manufactured by extrusion technology by an automatic production line of Elematic (Finland). Wall panels are manufactured by a high-tech, synchronous line, so they give high product quality, smooth surface, so there is no need to plaster (just bait and paint directly or paste wallpaper), can hang heavy objects. (such as kitchen cabinets, sanitary equipment, ...). XUAN MAI CORP is applying Acotec-Xuan Mai wall panel technology to replace traditional masonry walls in construction with the following outstanding advantages:

- Light load, which saves costs for load-bearing structures such as foundations, beams, floors.

- High strength and durability; moisture resistance, heat resistance, sound insulation, heat insulation, high fire resistance.

- Shorten construction time, save labor costs.

- The voids of wall panels are flexibly used to arrange electrical and water systems.

- High aesthetic, increase the clearance area compared to brick wall.

- Replace traditional bricks, overcome the disadvantages of unburnt materials in the climate of Vietnam.

- Application for high-rise apartment buildings, industrial buildings, soundproof walls, fences...

- In addition, when constructing Acotec-Xuan Mai wall panels, it also minimizes the use of loose materials and cutting chisels when constructing M&E. Therefore, the construction site is always clean, tidy, environmentally friendly, and does not generate waste or toxic waste.

Building information modeling (BIM) application management technology

Building Information Modeling (BIM) building a virtual model to analyze the overall design plan will help the Investor to optimize the investment problem from the very beginning. With the BIM model, the Investor can visually review the entire project from which to choose a functional layout plan, apply materials, and use energy efficiently to optimize benefits. while reducing investment costs.

Some information technology application solutions that have been applied by Xuan Mai are:

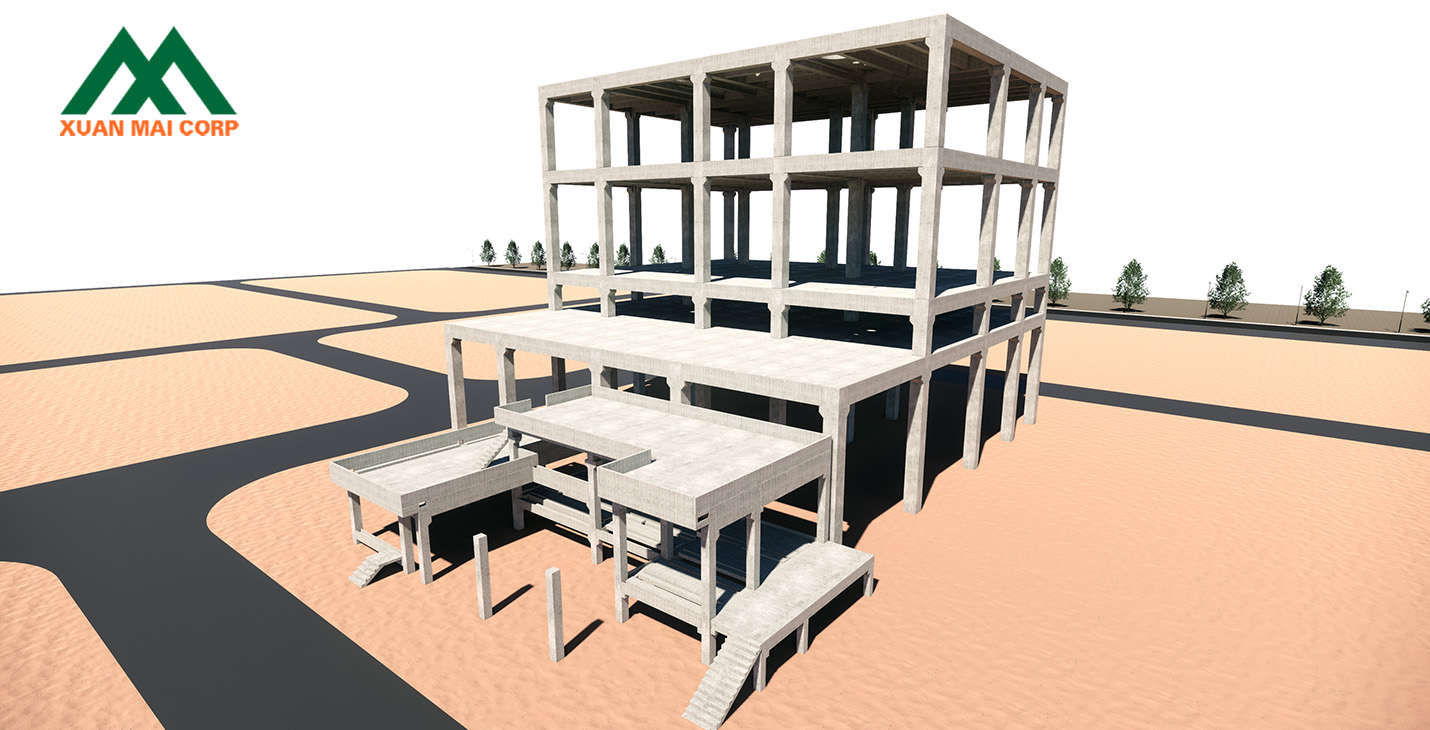

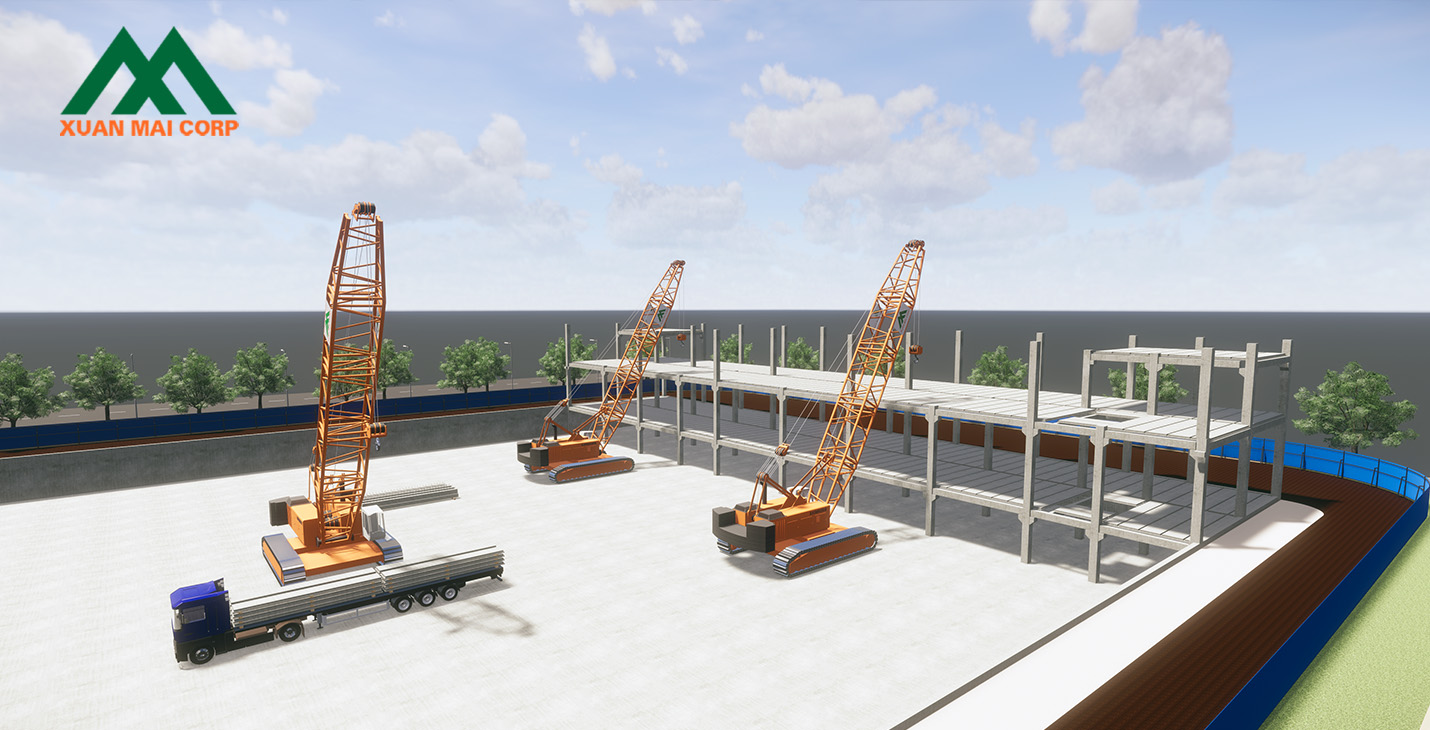

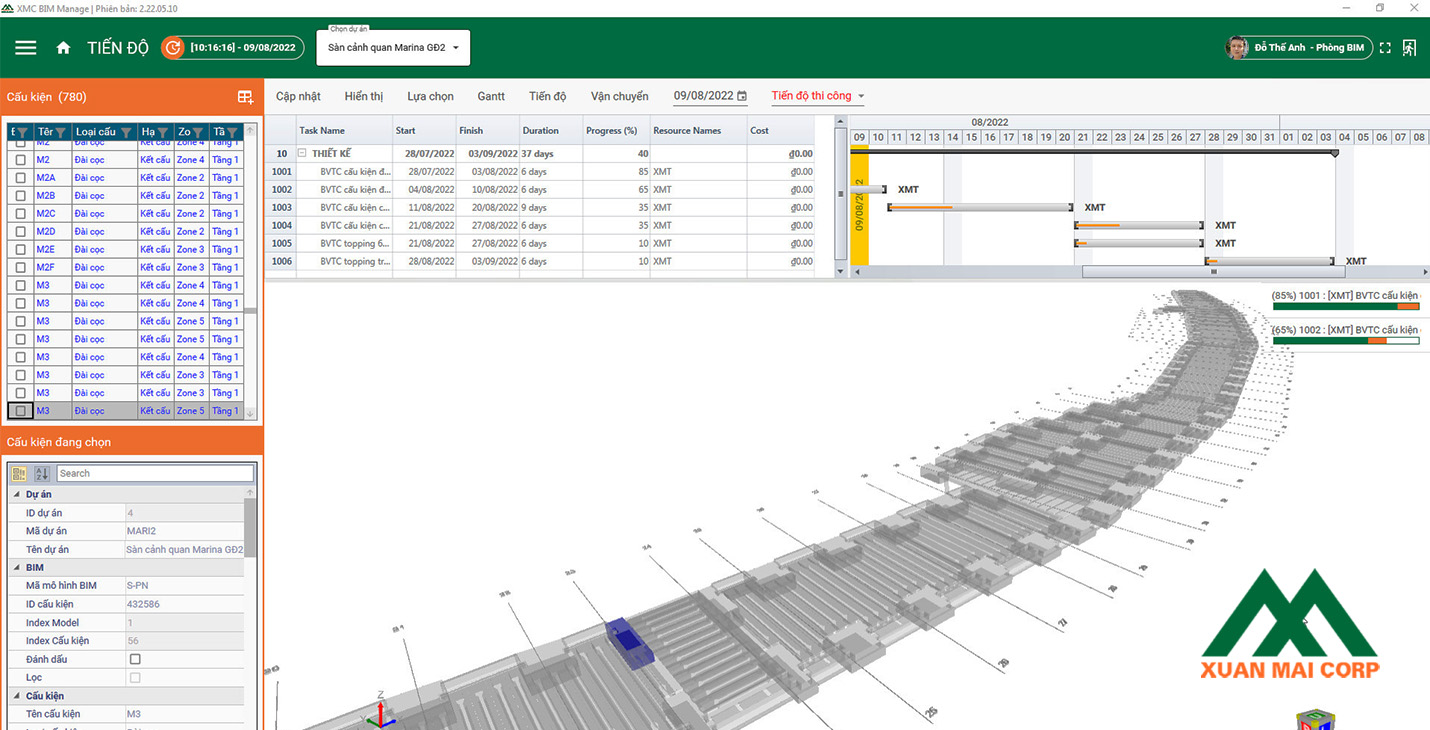

- BIM digital model of the actual project: The project will be built and updated continuously from the concept stage to detailed design, production, construction, and operation management. Thanks to that, Xuan Mai Corp can easily evaluate and choose the optimal solution on the virtual project from the very beginning, as well as reduce design errors and limit risks during construction.

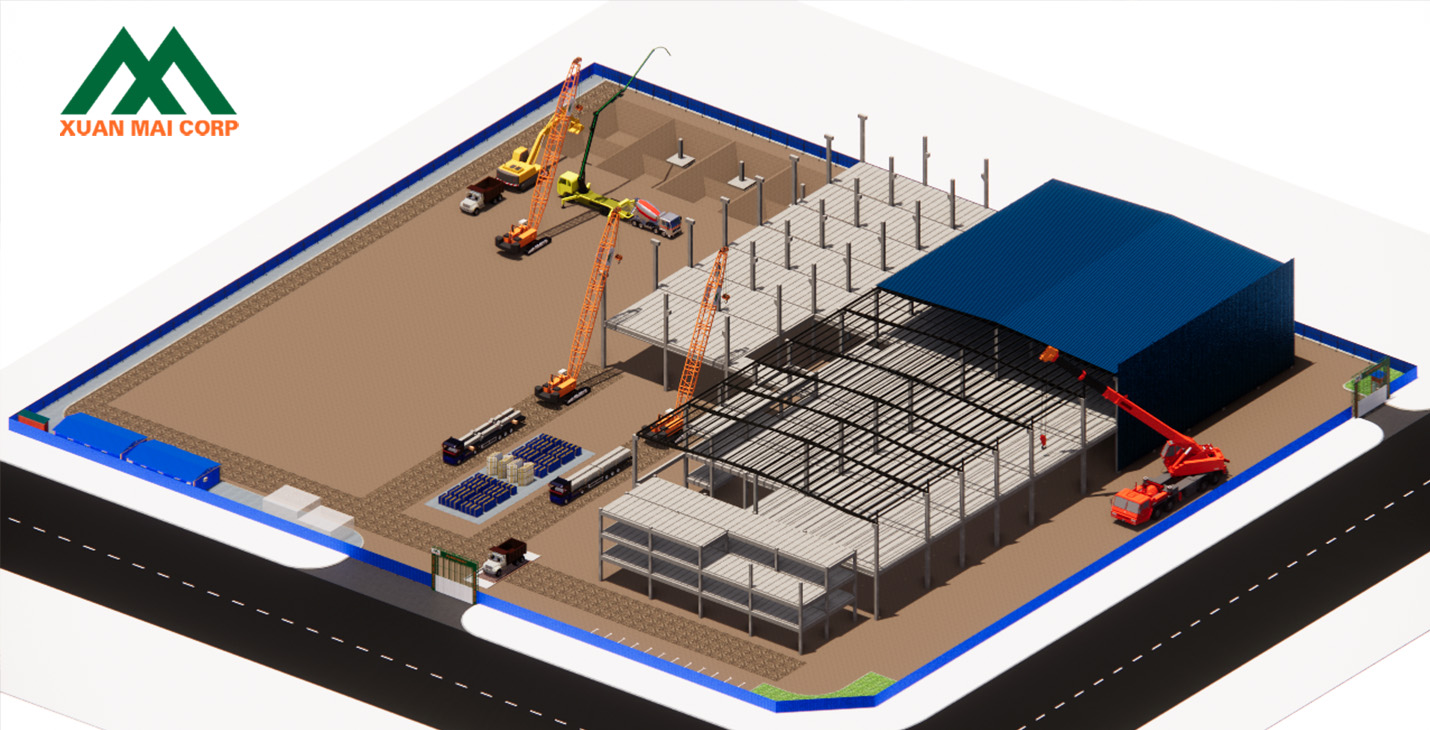

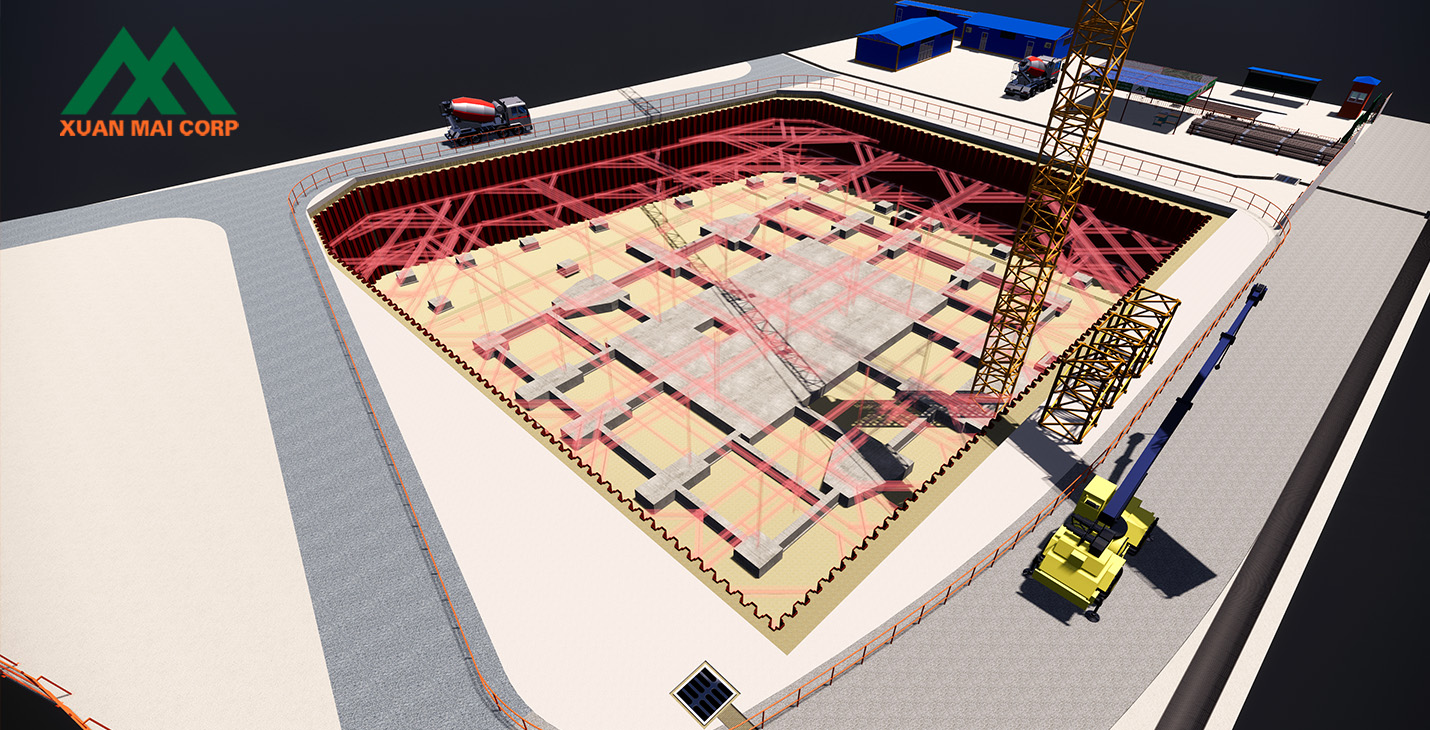

- BIM application to support construction measures.

- Xuan Mai also develops a system of management software through two-dimensional barcodes (QR Code), each component is coded, production, transportation and erection information is continuously updated with the environment. the common market, thus always monitoring the real-time production status of each component, thereby evaluating whether the production schedule is consistent with the plan or not.

- Along with the Digitized Model, all data about the project is uploaded to the cloud computing center (BIM Cloud), from which the design, production and construction units can bring information about the project, drawings, construction progress, production and erection time. As a result, managers can monitor project progress in real time anywhere, just an internet connection. In addition, the BIM Cloud system also provides analysis and assessment of the project's production and construction progress, thereby giving timely notifications and warnings.